Adaptive Automatons: How Cobots Evolve with Industry Needs

The industrial landscape has changed dramatically in recent years. Advanced manufacturing techniques like robotics, 3D printing, and automation have been around for a while, with an increasing impact on how goods are produced—greater efficiency and customization and delivering new speed levels to market. Yet through all these technological changes, the most versatile industrial worker has remained the same: human beings with unmatched talent, problem-solving aptitude, and ability to safely operate in unpredictable environments alongside machinery. A new generation of “cobots” aims to bridge this gap. Cobots, or collaborative robots, are engineered to work seamlessly alongside human coworkers through advanced sensors, vision systems, and flexible robotic arms designed from the ground up for safety. In this article, we’ll explore how cobots evolve their capabilities through machine learning, computer vision technologies, and intuitive user interfaces to take on an expanding range of industrial tasks while maintaining human-centered values of trust, transparency, and partnership.

The Evolution of Cobots

Cobots were first introduced in the late 1990s, but in the early 2010s, they started gaining traction in industrial settings. Initially, cobots were designed to take on repetitive and labor-intensive tasks to reduce strain on human workers and increase production efficiency. However, as technology advances, cobots have evolved to take on more complex and delicate tasks previously only possible for human workers.

One of the key factors driving this evolution is machine learning. Using algorithms and data analysis, cobots can continuously learn from their interactions with humans and improve their real-time performance. It allows them to adapt to changing environments and tasks, making them incredibly versatile and efficient workers.

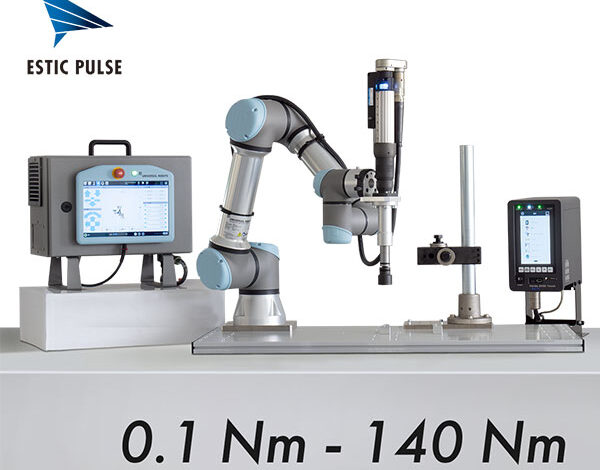

Computer vision technologies have also played a significant role in the evolution of cobots. Cobots can accurately detect and identify objects and people in their surroundings by combining cameras, sensors, and advanced software. This enables them to work safely alongside human coworkers without the risk of collisions or accidents. Check out ESTIC for more information.

Advancing Human-Centered Values

As cobots become more ingrained in the fabric of the modern workforce, a pivotal aspect of their evolution is the emphasis on advancing human-centered values. It includes designing cobots to perform tasks and enhance the quality of work life for their human collaborators. Safety is a prime concern, leading to the development of advanced safety features like collision detection and emergency response systems.

Additionally, ease of use is critical; intuitive programming interfaces are being developed, allowing workers without an extensive background in robotics to train and work with cobots efficiently. This democratization of technology fosters an inclusive environment where the focus is on augmenting human ability and creativity, not replacing it.

The Future of Cobots in Industry

It’s clear that cobots are here to stay, and their presence will only continue to grow as technology advances. In the future, we can expect to see more extensive use of machine learning and artificial intelligence in cobots, allowing them to adapt and take on increasingly complex tasks. We may also see collaborative robots combining their strengths to tackle more significant and intricate operations.

As cobots continue to evolve, it’s essential to maintain a focus on human-centered values. This means ensuring they are safe, easy to use, and designed with collaboration. By doing so, we can create a future where humans and robots work together seamlessly and efficiently for the benefit of all. So, while the industrial landscape may continue to change and evolve, one thing is for sure: cobots will be a vital part of that transformation. They truly are the adaptive automatons of the future.

What Are the Benefits of Cobots in Industry?

The tangible benefits of integrating cobots into industrial processes are multifaceted and substantial. Cobots excel in precision tasks and can work tirelessly, thus significantly increasing productivity and process consistency. This precision and endurance support industries in maintaining high-quality standards while meeting increased production demands. Moreover, when cobots take over monotonous or hazardous tasks, they mitigate workplace risks, contributing to a safer environment for human workers.

There’s also an economic upside to deploying cobots—they often require a lower investment than traditional robots. They can be repurposed across various tasks, offering a quicker return on investment. As they work alongside humans, cobots are quietly revolutionizing the workforce, making it both more efficient and adaptable to the rapid pace of change inherent in today’s industrial landscape.

In Conclusion

Cobots are a prime example of how technology can evolve and adapt to industry needs while maintaining human-centered values. Cobots have become essential and versatile workers in the industrial landscape by continuously incorporating advancements like machine learning and computer vision technologies. With their ability to work alongside humans safely and efficiently and with a focus on enhancing human abilities rather than replacing them, cobots are shaping the future of the industry for the better. As we continue to embrace and develop this technology, one thing is sure: the evolution of cobots is far from over, and it’s an exciting time to be a part of it.