bidrl:

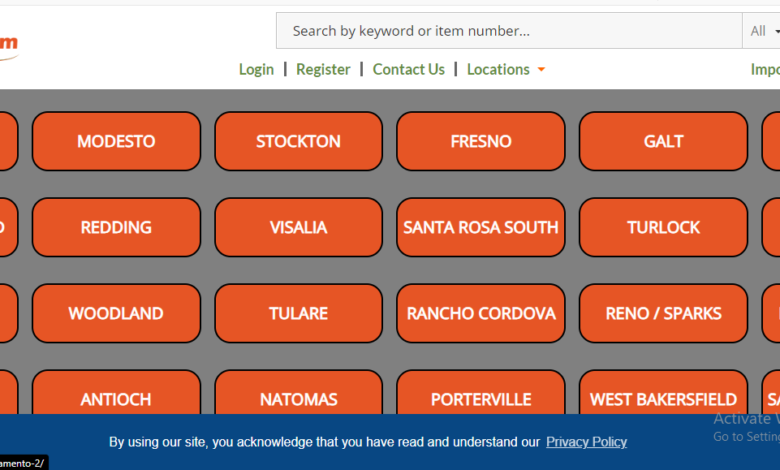

Bidrl = We take hard assets (stuff) and liquidate them (convert them into cash by selling them). We have been liquidating the assets of national big box retailers. It has almost 42.4K organic traffic. The Alexa Rank of the site is 204K.

Top Keywords:

| bidrl reviews |

| bidrl visalia |

| bidrl merced |

| bidrl santa rosa |

| bidrl marysville |

| bidrl reno |

| bidrl citrus heights |

| bidrl porterville |

Related to bidrl:

| bidrl modesto |

| bidrl sacramento |

| bidrl stockton |

| bidrl fresno |

| bidrl santa rosa |

| bidrl redding |

| bidrl turlock |

| bidrl visalia |

| bidrl merced |

| bidrl bakersfield |

bidrl Quick Stats:

| Alexa Rank | Dr | Da | Pa | Spam Score | Links |

| 204K | 24 | 35 | 42 | 2 | 1,331 |

Ranking Strategy :

Alexa:

Alexa is owned by Amazon and it is a web analytic corporation that calculates web metrics that are based on technical information collected from various sources which include toolbar and browser extensions.

Google:

Google uses thousands of algorithms to rank your website content in such a way preferred to the quality of content. Our Keyword and stat’s table take those things in concentration and then apply it to finalise the ranking table for you.

Moz:

Moz uses algorithms to calculate DA, PA, and Spam scores.

Ahref:

It finalises the Domain authority based on the density of quality backlinks.

Related Keywords:

bidrl, bid rl, rl liquidators, rl auction, auction